GSPCB has directed industries at Cuncolim IDC to monitor emissions, ETPs, and maintain slag disposal records; residents remain unconvinced and demand safe disposal of 35,000 tonnes of hazardous waste

The hazardous waste dump lying unattended at the Cuncolim Industrial Estate for the last 18 years.

File photo of effuents dischaged from Cuncolim IDC.

MARGAO

A recent report by the Goa State Pollution Control Board (GSPCB) has outlined several environmental initiatives undertaken at the Cuncolim Industrial Estate, aiming to curb pollution in the area, including measures to conduct Ambient Air Quality Monitoring under the National Air Monitoring Programme (NAMP) and Water Quality Monitoring under the National Water Monitoring Programme (NWMP).

In addition, the GSPCB has carried out environmental audits of fish meal and fish processing units operating within the estate. According to the report, industrial units have been directed—under their consent conditions—to implement a range of measures, including Ambient Air Monitoring, Stack Emission Monitoring, Effluent Treatment Plant (ETP) Monitoring, and maintaining detailed records of slag disposal.

However, despite these official claims, residents of Cuncolim—who have waged a long and sustained battle against pollution at the estate—remain unconvinced. Many locals argue that these measures have neither significantly reduced air and water pollution nor addressed the persistent foul odour that continues to emanate from the industrial area.

Adding to local concerns is the unresolved issue of hazardous zinc waste, estimated at around 35,000 tonnes, which has been lying unattended at the Cuncolim Industrial Estate for nearly 18 years. Residents are anxiously waiting for concrete action from the government and its agencies—including the GSPCB and the Department of Science, Technology and Waste Management—to safely dispose of the hazardous material.

Hope was recently rekindled when Chief Minister Pramod Sawant, speaking in the Goa Legislative Assembly, announced that Levinson Martins would soon be appointed as the new Chairman of the GSPCB, sparking optimism as well as a degree of scepticism. Optimism because Martins hails from the adjoining village of Assolna and is no stranger to Cuncolim given that he had presided over the GSPCB as its Member Secretary in the recent past. Scepticism for the simple reason whether a change in leadership alone can bring about a meaningful transformation at the long-polluted Cuncolim Industrial Estate when the system needs an overhaul to bring about a change on the ground.

No CETP yet for Cuncolim Estate housing heavy industry, fish units

Unlike many other industrial estates, the Cuncolim Industrial Estate plays host to steel and metal manufacturing units equipped with induction and reheating furnaces, along with fish processing and fish meal units, IMFL/ distilleries, and various other facilities.

Steel manufacturing units, in particular, require substantial quantities of water for processes such as production, cooling, pollution control, slag cooling, and even gardening. Currently, water for these needs is sourced from borewells, the IDC, and private tankers.

Similarly, fish processing units generate wastewater during the handling and processing of fish. This wastewater is reportedly treated in captive Effluent Treatment Plants (ETPs) installed within the units.

Regrettably, the Cuncolim Industrial Estate still lacks a Common Effluent Treatment Plant (CETP). Despite repeated assurances from the government regarding its establishment, the promises have thus far remained unfulfilled.

Vigilant residents have repeatedly highlighted incidents of effluents from the estate making their way into nearby water bodies and rivulets. This has led to contamination of local water resources, raising serious concerns about the adequacy and effectiveness of existing wastewater treatment practices at the Cuncolim Industrial Estate.

Recycled effluent from fish units used in steel units, but impact limited

The GSPCB report indicated that the board had initiated measures to encourage the fish units to supply the ETP treated water to the steel units for slag cooling, mills cooling, gardening, dust suppression, scrubbers. In fact, the process of supplying the treated water from the fish units to the steel units had started some months ago.

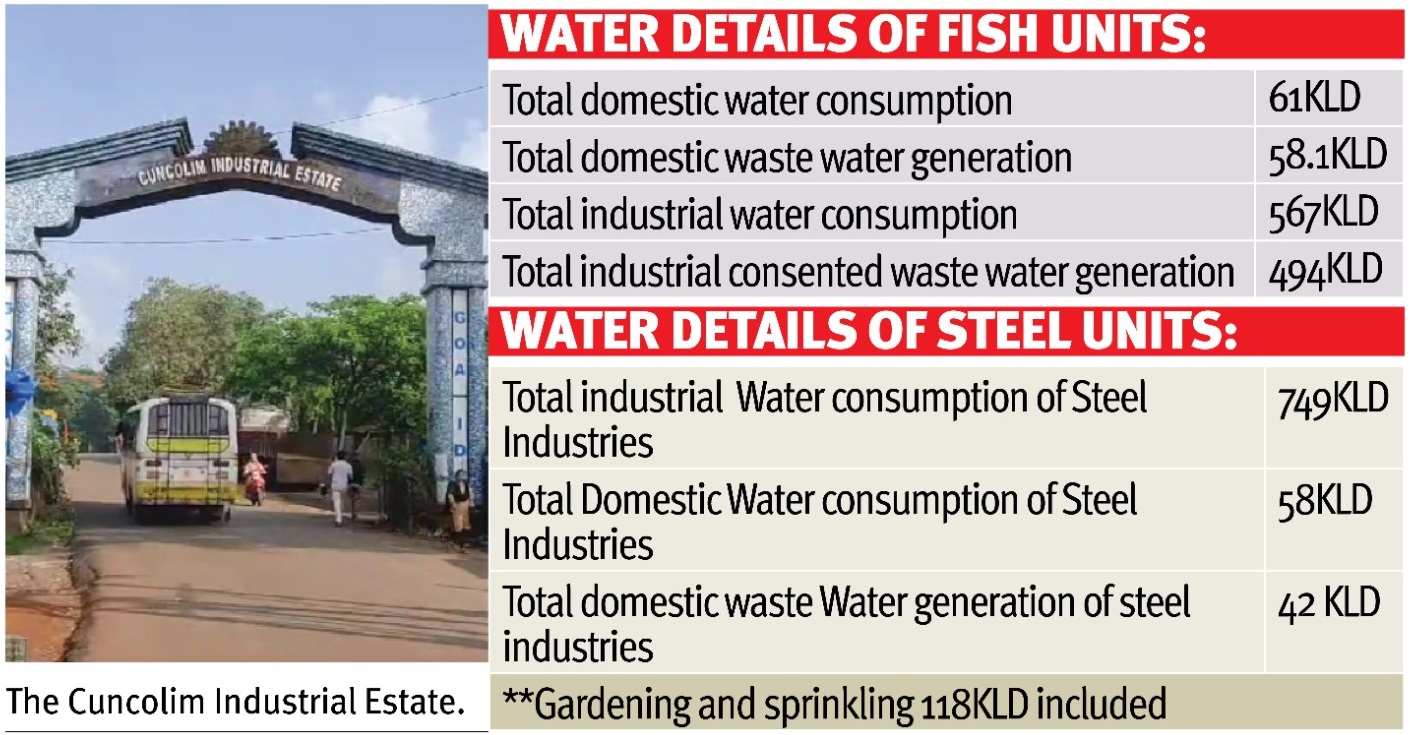

The GSPCB report says that approximately 30KLD is recycled from the fish meal/processing units for cooling purpose in steel manufacturing units reducing overall ground water withdrawal. A comparison of the water details of the steel units and fish units, including their water consumption, both domestic and industrial and waste generation, however, shows that the amount of water recycled may form a small percentage of the total water requirements of the steel units.

The GSPCB report stated that the units should provide Electromagnetic Flow meters at the inlet and outlet of ETP. The same should be connected to board’s server from receipt of this addendum.

The units should install On-Line Continuous Effluent Monitoring System (OCEMS) on the treated effluent discharge pipeline for measurement of Flow, pH, COD, BOD, TSS and TDS and should provide a connectivity to GSPCB server from receipt of this addendum.

GSPCB launches odour study amid complaints

Residents staying in the vicinity of the Cuncolim Industrial Estate complain of the foul odour emanating from the area. In fact, they have pointed out that they have been plagued by unbearable odour since the time the fish meal and fish processing units set shop in Cuncolim. Promises to control odour have in no way mitigated the problems faced by the residents.

The GSPCB report, however, said that an odour study has been initiated by the Board for Cuncolim in September 2024. In fact, the Board has awarded the work of odour monitoring and characterisation of odorous compounds around Cuncolim IDC to a firm.

The Board has identified the odour generating units as fish processing units (6 nos. washing and packing units and 1 fish meal unit).

The report says that around 20-22 locations will be identified by GSPCB. Some locations will be selected in the core and buffer zone of some of the industrial units and some locations in the residential area nearest to the IDC.

Locals allege furnace smoke escapes into air and not through chimneys

The GSPCB report shows that the steel units are directed to install online stack monitoring system for the furnaces and connect the same to Board servers for continuous monitoring. Board officials also conducted inspection of steel units and has directed the steel owners to rectify and increase the flue gas suction hoods. Inspection has been done and show cause notice has been issued to four units.

The report further states that around eight steel units have stopped its operations at Cuncolim, while a few have converted to direct hot rolling rather than reheating thereby further reduction in emission load, resulting in a decrease in the overall emissions from the steel manufacturing units.

Residents and anti-pollution activists, however, beg to differ. They question how come the smoke generated in the units does not come out of the chimneys but is spread in and around the units.

New GSPCB chief has task cut out to cart away hazardous dump

Chief Minister Pramod Sawant has promised on the floor of the ongoing session of the Goa Legislative Assembly that the hazardous waste will be carted out of Cuncolim IDC by October. In fact, the new GSPCB Chairman Levinson Martins has a task cut out – to move the file to the government for funding of the transportation cost to cart away the waste to Pissurlem.

After NEERI confirmed that the waste left behind by Ms Sunrise Zinc way back in 2008 is hazardous in nature, the GSPCB dashed off a letter to the Department of Science, Technology and Waste Management to appoint an agency to transport the waste from Cuncolim to Pissurlem.